SCROUNGER™ Jr Oil Skimmer

Effectively Remove Oil from Coolants and Washing Solutions

Tramp oil is a major source of problems associated with water miscible cutting and grinding fluids.

Tramp oil contributes to the growth and formation of:

- coolant-destroying bacteria

- undesirable residues on machine tools and workpieces

- smoke and oil mist in shop atmospheres

These problems result in:

- shortened coolant life

- poor material removal rates

- poor surface finish and size control

- decreased tool and wheel life

Numerous devices ("floating ropes," wheels, and belts) have been developed over the years to remove "free floating" tramp oil from the surface of coolant. While they have all worked to one degree or another, they generally have been either "troublesome," high maintenance, relatively ineffective, or able to operate only on limited liquid level fluctuations.

As a "belt-type" skimmer, these units are effective in removing floating oil from widely fluctuating liquid levels of coolants or parts washing solutions. The SCROUNGER features a revolutionary new oleophilic belt and a totally new concept of stripping the separated oil from the belt. The SCROUNGER Jr. uses the same "oil loving" belt, but uses a more compact scraper blade to strip the separated oil from the belt.

Features

- 115 volt, single phase, 50/60 Hz

- heavy-duty, impedence-protected, fan-cooled drive motor with hardened shaft and needle bearings (220 volt,

single phase, 50 Hz also available)

- open, accessible oil-collecting tray with a convenient drain connector

- "oil loving" oleophilic belt (purchased separately)

- heavy-duty steel construction, with industrial-grade enamel paint

Benefits

- fast, simple belt changing

- low maintenance

- lower hang roller that will not fall off in the machine sump even in turbulent conditions

Options

- dewatering tray

- portable kit

- special length belts available on special order

- special belt materials available for high temperature or pH applications on special order

SCROUNGER Jr Belts

- all belts 1" [25mm] wide

- 24" [610mm]

- 32" [815mm]

- 44" [1120mm]

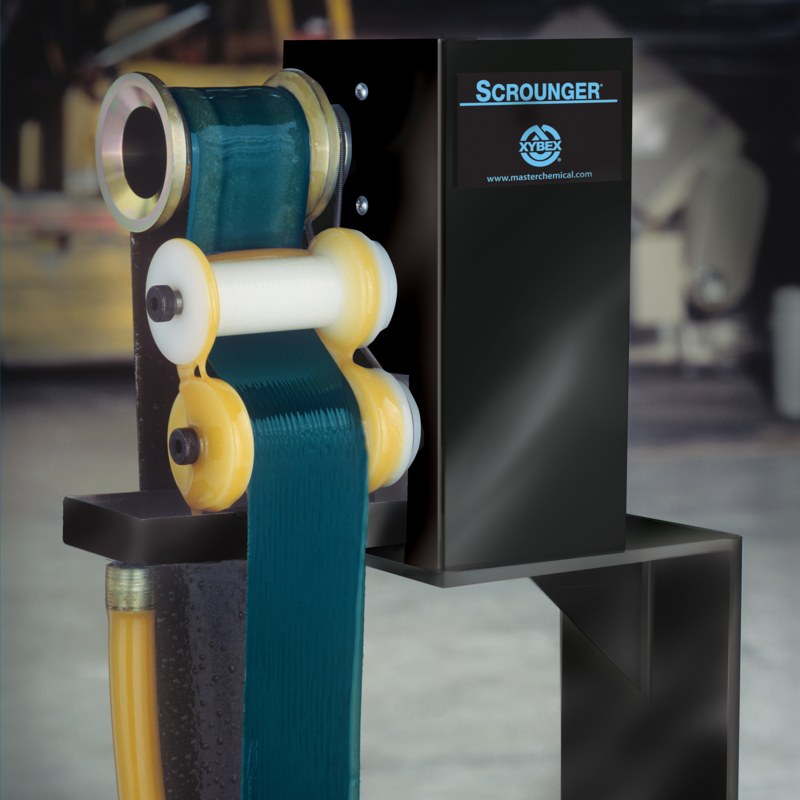

SCROUNGER™ Oil Skimmer

Effectively Remove Oil from Coolants and Washing Solutions

Tramp oil is a major source of problems associated with water miscible cutting and grinding fluids.

Tramp oil contributes to the growth and formation of:

- coolant-destroying bacteria

- undesirable residues on machine tools and workpieces

- smoke and oil mist in shop atmospheres

These problems result in:

- shortened coolant life

- poor material removal rates

- poor surface finish and size control

- decreased tool and wheel life

Numerous devices ("floating ropes," wheels, and belts) have been developed over the years to remove "free floating" tramp oil from the surface of coolant. While they have all worked to one degree or another, they generally have been either "troublesome," high maintenance, relatively ineffective, or able to operate only on limited liquid level fluctuations.

As a "belt-type" skimmer, these units are effective in removing floating oil from widely fluctuating liquid levels of coolants or parts washing solutions. The SCROUNGER features a revolutionary new oleophilic belt and a totally new concept of stripping the separated oil from the belt. The SCROUNGER Jr. uses the same "oil loving" belt, but uses a more compact scraper blade to strip the separated oil from the belt.

Features

- 115 volt, single phase, 50/60 Hz

- heavy-duty, impedence-protected, fan-cooled drive motor with hardened shaft and needle bearings (220 volt,

single phase, 50 Hz also available)

- open, accessible oil-collecting tray with a convenient drain connector

- "oil loving" oleophilic belt (purchased separately)

- heavy-duty steel construction, with industrial-grade enamel paint

Benefits

- fast, simple belt changing

- low maintenance

- lower hang roller that will not fall off in the machine sump even in turbulent conditions

Options

- dewatering tray

- portable kit

- special length belts available on special order

- special belt materials available for high temperature or pH applications on special order

SCROUNGER Belts (purchased separately)

- all belts 3" [76mm] wide

- two foot hang: total length 70" [1780mm]

- three foot hang: total length 94" [2390mm]

- four foot hang: total length 118" [3000mm]

- six foot hang: total length 166" [4220mm]

Sump Side Coalescer™

Simple to operate, lower-cost coalescer for smaller shops removes tramp oil even with large sumps

Features

- 15-gallon polypropylene settling tank with lid and clamp

- includes GFI adapter

- easily modified for sumps just 3" deep

Options

- double-diaphragm models available for deep sump applications

- larger electric pump unit for mounting higher on or further from the sump

- Scrounger® Jr Oil Skimmer for automatic removal of tramp oil from tank

Specifications and Utilities

- Process rate: 1 to 2 GPM (4 to 8 LPM)

- Dimension of tank: 18" w x 23" h (457mm x 584mm)

- Electric: 110 volt, single phase, 60Hz

Tramp Oil Terminator™

Portable Centrifuge Unit for Removing Emulsified Tramp Oils

Developed to meet the needs of the small metalworking plant for a compact, portable, high-speed centrifuge, tramp oil separator, the Tramp Oil Terminator™ will process both water-miscible coolants and aqueous cleaners to remove free and emulsified tramp oils, providing clean and reusable coolants and cleaners. Removing tramp oils (hydraulic oils, way lubes or any undesirable oil) from coolants and cleaners removes a food source for bacteria, reduces undesirable residues, and reduces smoke and oil mist in the shop atmosphere.

Benefits

- Extended life of coolants and cleaners

- Improved machining

- Longer tool life

Features

- Compact and portable for machine tool sumps and parts washers

- Simple operation

- High-speed, disc-bowl centrifuge

- Stainless-steel hood and bowl

- Built-in clean fluid centripetal discharge pump

- Easy dismantling of bowl for cleaning

- Quick disconnects on feed and discharge

- Strainer and 50 micron cleanable pre-filter

- Air pump and floating skimmer for feed

- Automatic shut off when tramp oil collection tank is full

XYBEX™ ChipOut™

Chip & Sludge Remover

A perfect match-up with the PurifierPlus is the XYBEX ChipOut. It is also a compact, easy-to-use, affordable solution for optimizing production. It simply and effectively sucks out the coolant, chips, and swarf to collect and filter all solid impurities and return clean coolant to the tank.

Get the most from your coolant with ChipOut. It literally pays for itself in no time with significant cost savings.

XYBEX ChipOut

- Separates surface debris, bottom chips and swarf, and sediment from coolant

- Extends coolant life

- Improves surface finish on parts

- Reduces maintenance

- Uses diaphram pump air pressure, no electricity required

- High suction power, flow rate of 180 liters/min

- Runs during production without shutting off machine tools

- Adjustable stainless steel filters: standard mesh 380 microns; optional: 830 microns and 180 microns

- Optional floating device for maximum tramp oil collection

- Portable and easy to use with multiple machines

- Operates with water-soluble coolants or neet oils

Cost effective ChipOut adds up to big savings

- Reduces annual coolant cost

- Reduces expensive parts rejects

- Reduces maintenance to a minimum

XYBEX™ ChipOut Plus™

Magnetic Centrifugal Sludge & Chip Remover

Looking for a fast, affordable way to have longer coolant life, reduce maintenance, and achieve better machinability and surface finish? Hardworking ChipOut Plus delivers all that and more in a compact, portable system that can hook up to machines throughout the shop.

It does double time, as both a centrifugal and magnetic separator for water-based cutting fluids or neat oils. It’s simple to use, powerful, and efficient.

First, the suction hose draws in the liquid and impurities. The filtration bucket traps large impurities before the sludge-containing fluid enters the centrifugal separator where fine particles are separated out by centrifugal force. The sludge then enters the powerful magnetic separator which efficiently removes magnetic metallic shavings and particles. Just like its name implies, it takes out chips - plus more!

XYBEX ChipOut Plus

- Separates surface debris, magnetic dust and shavings, chips, swarf, and sediment from coolant

- Extends coolant life

- Improves surface finish on parts

- Reduces maintenance

- Separates using centrifugal and magnetic force

- Provides extremely fine filtration

- No need to stop the machine

- Quick filtration, easy to operate

- Portable, use with multiple machines

- No consumables needed

Use hardworking, cost effective ChipOut Plus to reduce costs and build profits

Save time and build up profits with ChipOut Plus.

- Reduces annual coolant cost

- Reduces maintenance and manpower

- Reduces costly parts rejects

XYBEX™ PurifierPlus™

Cutting Fluid Purifying System

The portable, cost-effective XYBEX PurifierPlus system pays for itself with material cost savings, reduced downtime and recycling costs. Not only does it enhance production and make the workplace cleaner, it also is better for employee health and the environment.

Unlike units which simply separate machine tramp oil (the unwanted byproduct of the machining/metalworking process) from coolant, PurifierPlus has an ozone disinfection function which kills bacteria. Not only is the coolant cleaned and lasts longer, it’s purified and reused, and the subsequent problematic stench from bacteria and fungal growth is eliminated.

Improve production, reduce costs, and experience a cleaner workplace with PurifierPlus.

XYBEX PurifierPlus

- Separates free tramp oil and extends coolant life

- Reduces tool wear and costly parts rejects

- Easy to use with a handy set-timer to operate on its own

- Adjustable flow rate filter from 10 to 30 liters/hr

- Kills bacteria (for best results run 1 hour for each 100 liters in sump; ozone function disinfects at 500 mg/hr)

- Built-in pH detector (optional) adjusts pH to control range

- Portable for use on multiple machines in the facility

PurifierPlus quickly pays for itself in savings

- Saves 10% to 25% on annual coolant cost

- Saves 30% to 50% on additional water cost

- Saves 10% to 25% on tooling costs and part reworks

- Reduces clean-up time 60% to 80% annually