by Nichole Schalk-Tiell | Feb 20, 2025 | Blog

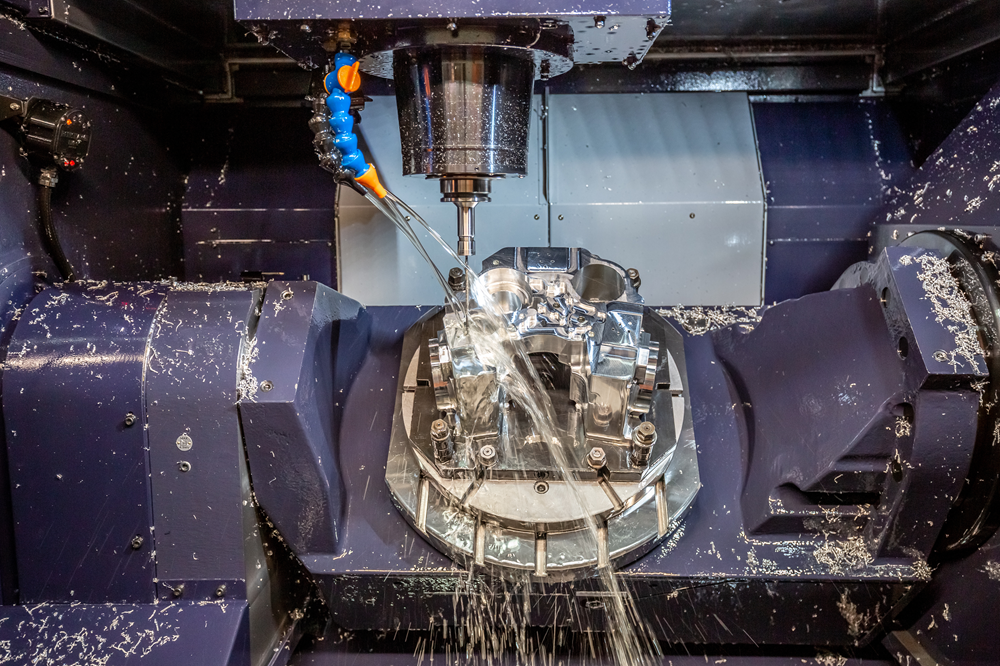

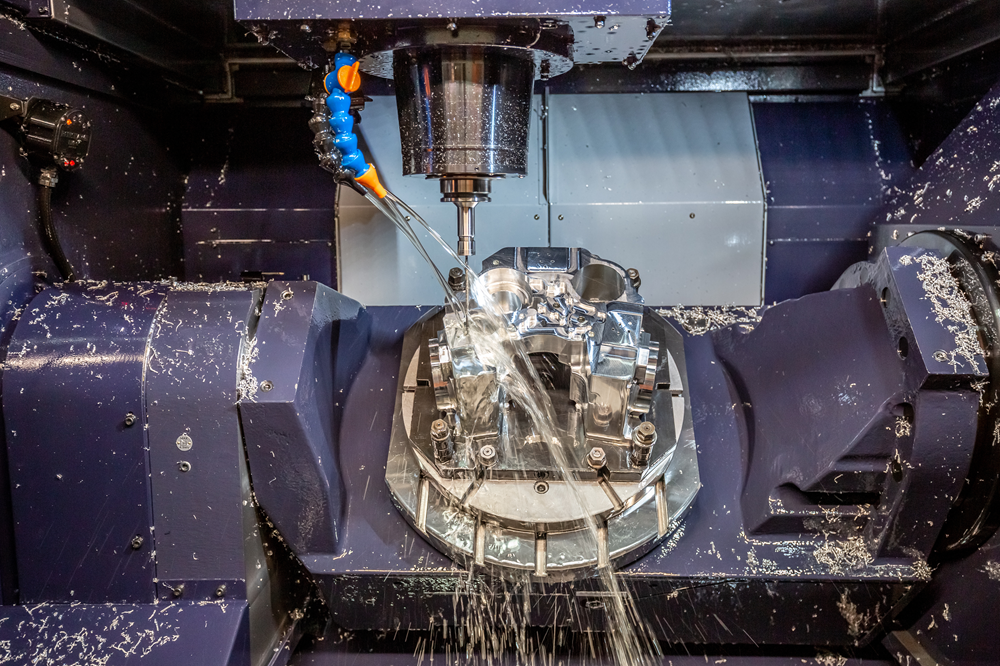

In metalworking, the efficiency and longevity of metalworking fluids (MWFs) are critical to maintaining productivity and controlling costs. Proper fluid maintenance ensures peak performance, reduces waste, and protects both machinery and workers. By following a few essential best practices, manufacturers can maximize fluid life, enhance operational efficiency, and achieve sustainability goals.

Read More

by Nichole Schalk-Tiell | Feb 6, 2025 | Blog

In today’s competitive manufacturing landscape, efficiency isn’t just a goal – it’s a necessity. Industrial fluids, like cutting fluids and lubricants, are the lifeblood of modern machining operations, directly influencing tool life, product quality, and overall operational costs. However, achieving optimal fluid performance requires more than just selecting the right product. It demands a strategic approach to fluid maintenance.

Read More

by Master Fluid Solutions | Jan 29, 2025 | Blog

AI is revolutionizing the way industries achieve efficiency and precision. Metalworking and manufacturing are no exception, and these industries are investing heavily in it.

Read More

by Mike Dumont | Jan 29, 2025 | Blog

Metalworking shops spend a lot of time optimizing the usual suspects: machinery, tooling, and throughput. Even training and upskilling have gotten a large boost in the last few years. But one factor often overlooked? Choosing and maintaining the right cutting fluid. The problem, though, with neglecting your fluid is that it can mean the difference between your shop running at 110% versus struggling to hit 50%.

Read More

by Nichole Schalk-Tiell | Jan 20, 2025 | Blog

In today’s competitive manufacturing landscape, every operational detail matters. From reducing downtime to ensuring peak performance, companies are continually looking for ways to do more with less. One often overlooked area with significant potential is coolant management. By implementing smarter strategies, manufacturers can unlock cost savings, enhance equipment performance, and achieve greater sustainability—all while maintaining superior product quality.

Read More

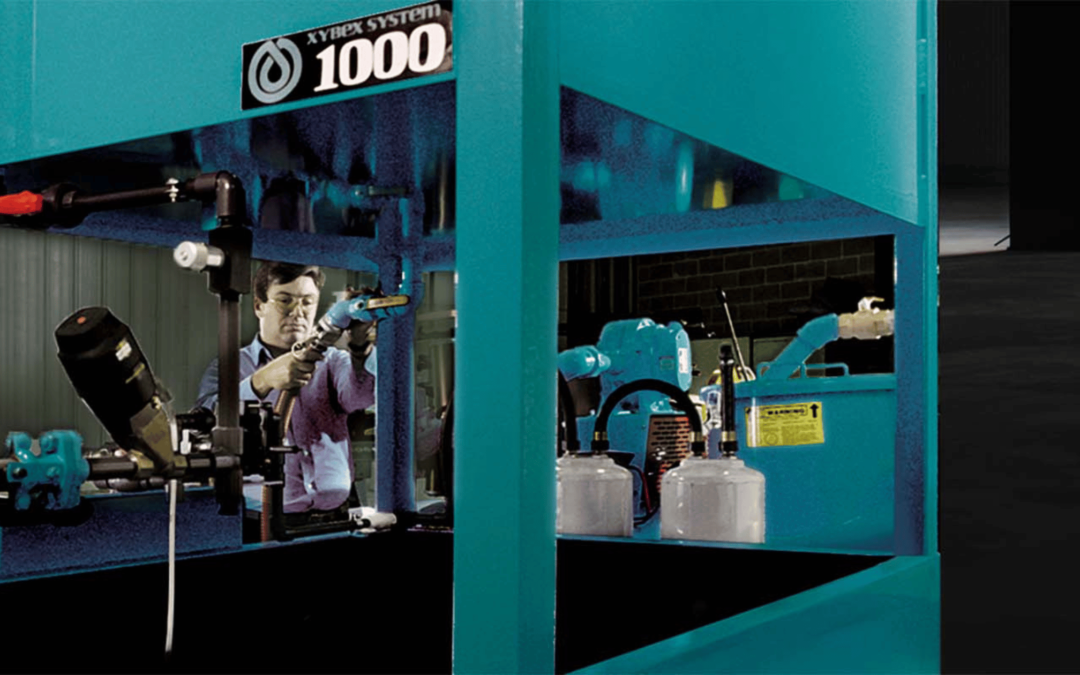

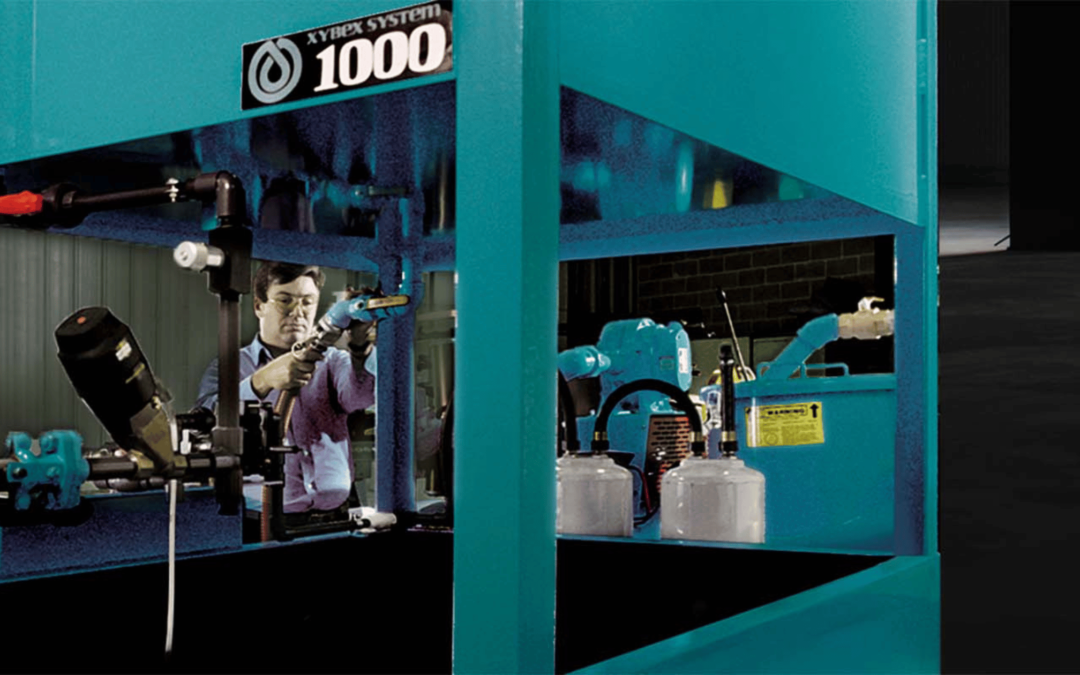

by Nichole Schalk-Tiell | Jan 13, 2025 | Blog

In manufacturing, metalworking, and industrial operations, the hidden backbone of success often lies in maintaining fluid systems. At Master Fluid Solutions, we know that proactive maintenance isn’t just about avoiding downtime—it’s about creating opportunities for efficiency, cost savings, and long-term operational excellence.

Read More

by Rob Dodson | Dec 2, 2024 | Blog

Product diversification is a key strategy for manufacturing success in the 2020s. Does your operation have the right foundation in place?

Read More

by Mike Nemet | Dec 2, 2024 | Blog

American industrial capacity remains below pre-pandemic levels, even as reshoring ramps up. Here’s what it takes to grow.

Read More

by Master Fluid Solutions | Sep 5, 2024 | Blog

Machine shops are in dire need of skilled workers. These are the four manufacturing skills the industry needs to fill the gap.

Read More

by Master Fluid Solutions | Aug 30, 2024 | Blog

Sustainable manufacturing isn’t just the future — it’s a pathway to long-term profitability. Here’s why you need to get started on the journey.

Read More